A construction crane weighing 12000 lbf – At the heart of construction sites, the construction crane weighing 12000 lbf stands tall, a testament to engineering prowess and the backbone of modern construction. Its towering presence and remarkable lifting capabilities make it an indispensable tool, shaping skylines and transforming landscapes.

From its inception to its current technological advancements, this paper delves into the intricate details of a construction crane weighing 12000 lbf, exploring its engineering specifications, load capacity, stability mechanisms, lifting mechanisms, safety features, applications, and the technological advancements that are revolutionizing its operation.

Construction Crane Engineering and Operations

Construction cranes are indispensable tools in modern construction projects. These colossal machines are responsible for lifting and placing heavy materials and structures, enabling the construction of high-rise buildings, bridges, and other complex structures.

Engineering Specifications

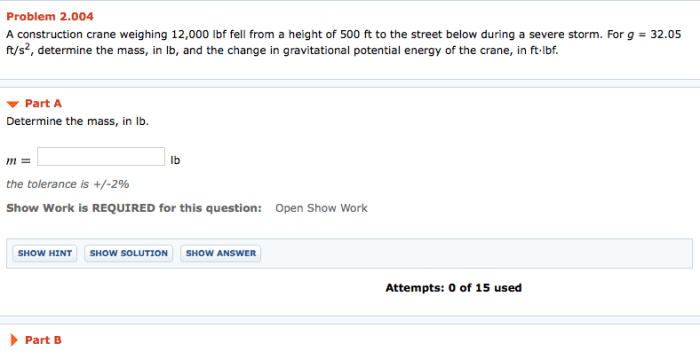

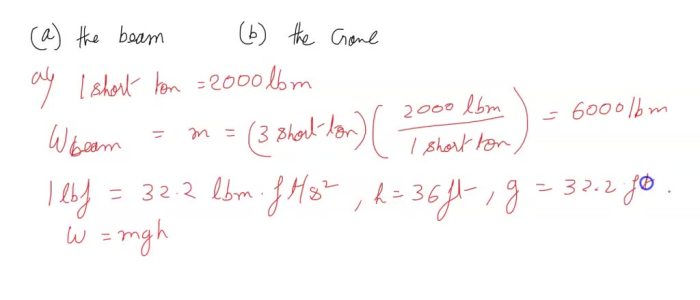

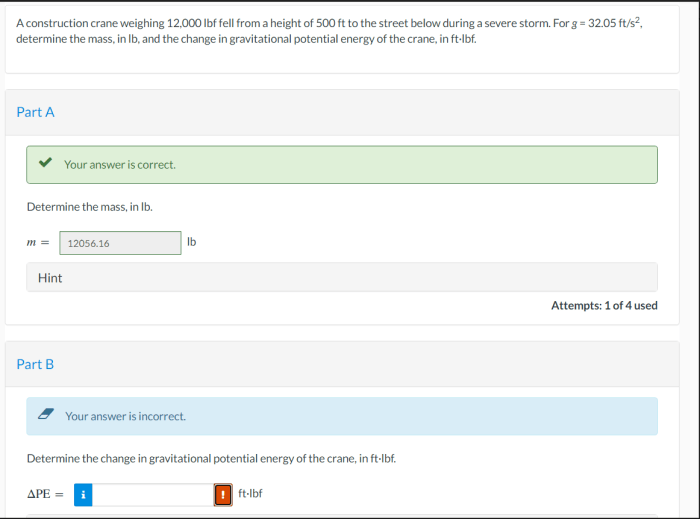

Construction cranes are designed to meet specific engineering specifications to ensure their safety and efficiency. The weight of a construction crane can vary significantly, typically ranging from 10,000 to 200,000 pounds (4,500 to 90,700 kilograms). The weight is determined by the crane’s capacity, reach, and overall design.

There are various types of construction cranes, each suited for specific tasks. Tower cranes are commonly used for high-rise construction, while crawler cranes are employed for heavy lifting on uneven or unstable ground. Mobile cranes offer versatility and can be easily transported between job sites.

Load Capacity and Weight Distribution, A construction crane weighing 12000 lbf

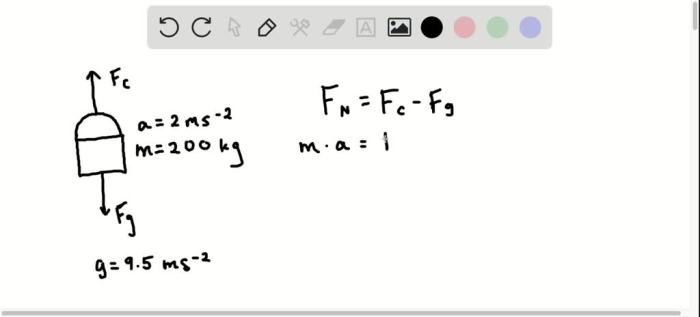

The load capacity of a construction crane is crucial for determining its suitability for a particular project. The capacity is determined by factors such as the crane’s design, boom length, and counterweight. To ensure stability, the crane’s weight distribution must be carefully calculated.

The weight distribution of a crane is typically divided into two categories: dead weight and live weight. Dead weight refers to the weight of the crane itself, while live weight includes the weight of the lifted load and any additional attachments.

| Crane Model | Load Capacity (tons) | Dead Weight (tons) | Live Weight (tons) |

|---|---|---|---|

| Tower Crane | 20 | 50 | 70 |

| Crawler Crane | 100 | 80 | 180 |

| Mobile Crane | 50 | 40 | 90 |

Stability and Counterweights

Stability is paramount for construction cranes, as it prevents them from tipping over under heavy loads. To enhance stability, counterweights are used to balance the crane’s weight distribution. Counterweights can be attached to the crane’s base or suspended from the boom.

The type and weight of the counterweight depend on the crane’s capacity and the weight of the load being lifted. Proper counterweighting ensures that the crane’s center of gravity remains within the stability triangle, which is a critical safety measure.

Lifting Mechanisms and Safety Features

Construction cranes employ various lifting mechanisms, including winches, hoists, and hydraulic systems. These mechanisms enable the precise control of the load, allowing for safe and efficient lifting operations.

Crane operation involves strict safety regulations and procedures. Crane operators must undergo extensive training and certification to ensure their competence in operating these powerful machines. Safety features such as overload protection systems, emergency brakes, and wind sensors are essential for preventing accidents.

Applications and Industries

Construction cranes are utilized in a wide range of industries, including construction, infrastructure, and manufacturing. They are indispensable for projects such as building skyscrapers, erecting bridges, installing wind turbines, and assembling industrial equipment.

The versatility of construction cranes allows them to adapt to various construction environments and project requirements. They play a vital role in enabling the construction of modern infrastructure and buildings.

Technological Advancements

Technological advancements have significantly enhanced the design and operation of construction cranes. Computer-aided design (CAD) and simulation tools enable engineers to optimize crane design and ensure their stability and safety.

The emergence of autonomous and remote-controlled cranes holds the potential to further improve safety and efficiency in crane operations. These technologies allow for the remote monitoring and control of cranes, reducing the risk of accidents and improving overall productivity.

User Queries: A Construction Crane Weighing 12000 Lbf

What is the purpose of a construction crane?

A construction crane is a versatile machine used to lift and move heavy materials, primarily on construction sites.

What factors determine the load capacity of a construction crane?

Load capacity is influenced by factors such as crane design, boom length, counterweight, and working radius.

What safety features are associated with crane operation?

Safety features include overload protection systems, anti-two block devices, and emergency stop buttons.